Rollstock film

Rollstock is film that has been rolled up to be used in packaging equipment that will shape and form the bag. BSY can fully customize any rollstock as we develop, extrude, laminate, slit, coat and print the film in house. This allows us to control and maintain the highest quality standards throughout the production process. All other markets especially food products can benefit from the same safety and quality control standard certified by ISO 9001 and HACCP PACsecure.

Rollstock films are available are available up to 51” or 1.3 metres wide on either 3” or 6” cores. You can print up to 12 colors on Rotogravure or Flexographic. BSY offers many different structures and materials but the most popular categories are:

- Degradable Films

- High Barrier Films

- Functional Films

Vertical Form Fill Seal VFFS Rollstock

The Vertical Form Fill and Seal (VFFS) machine application forms the film into the shape of a tube (pouch), fills the pouch vertically with product, and then seals the pouch. This is different from filling a finished bag because the bag is made along with the filling process. Rollstock used in Vertical Form, Fill, and Seal (VFFS) machines can package a variety of consumer products, mostly in loose form, such as: cereal, chips, nuts, coffee, pet food, detergent, and candies. These items are dispensed and dropped in a vertical matter into formed pouches and then sealed.

Horizontal Form Fill Seal HFFS Rollstock

Horizontal Form Fill and Seal (HFFS) machines application forms the film into the shape of a horizontal tube, fills the pouch horizontally with product, and then seals the pouch. Horizontal machines are mainly used for solid products such as candy bars, granola bars, and trays of cookies. Instead of having the product dropped vertically, it is rather slid horizontally inside the package.

Other rollstock applications:

- Cold seal

- Forming and thermo forming films

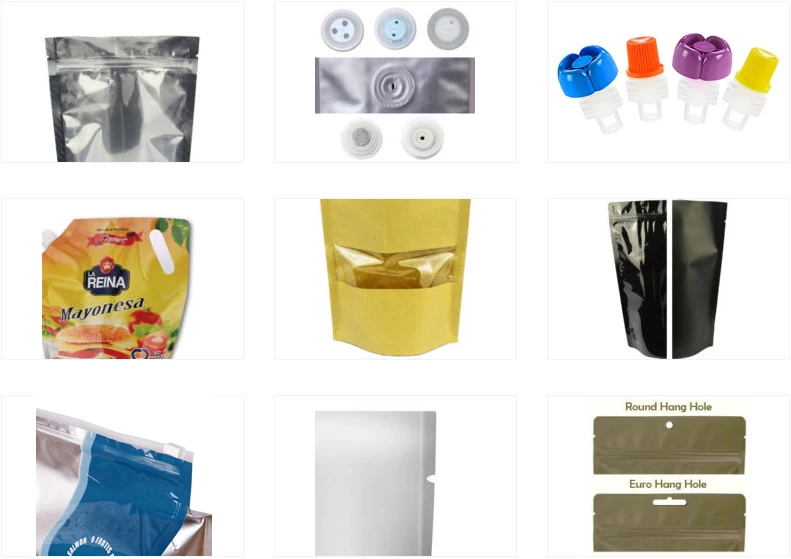

Stand Up Pouch

Stand Up Pouches, sometimes referred to as SUPs, are a popular format for food packaging. The reason the bag stands up is because of the gusset at the bottom. When the bag is filled, the bottom flattens out, which allows it to stand straight up on a store shelf. Stand up pouches are a convenient, light-weight and economic packaging solution for many food, consumer and retail applications.

Why choose stand-up pouches?

Stand up pouches are a popular consumer format because:

- it fits easily in crowded spaces because it’s flexible and not rigid

- with reclosable options like the zipper, it can be reused multiple times

- high visual impact on the store shelf due to the large visual front and back panels

- most efficient and cost effective to produce as it requires the least amount of raw materials when compared to glass, metal or rigid plastic containers

- it is environmentally friendly: takes up less space, costs less to transport, and uses less energy to produce

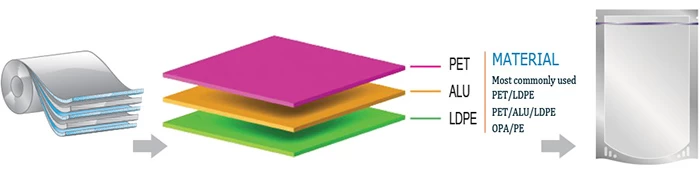

Understanding the technical side of packaging can get very complicated, some packages are made from multiple barrier films that are laminated together. This protects the contents inside, prolongs the products' shelf life, and gives the bag or pouch the strength to stand up effectively on the store shelf. Stand up pouches can be landfill friendly, recyclable and one of the lowest cost packaging options available when compared to other packaging alternatives such as can, glass and rigid containers.

Flat-bottom Bag

The flat-bottom pouch gets its name from bottom panel being completely flat. It may also be referred to as a box pouch because it resembles a box from the front. This format is an improved variation of the standard stand up pouch. The main difference is that it has five panels sealed together giving you more presentation area. Because the pouch is flexible, it can take up less room in a crowded cupboard space than a rigid format.

Why choose a flat-bottom bag?

This highly desirable flat-bottom bag offers incredible shelf stability due to its sturdy, level bottom. Because the base is flat and secure the flat-bottom bag is the ideal packaging solution for many consumer products such as cereal, rice, coffee, tea or pet food. Premium brands in the pet food, sports nutrition, grains and coffee market sectors are trending rapidly towards this packaging format.

Flat-bottom bag applications

The flat-bottom bag can be used for many food packaging and retail applications. Some of the most common and popular markets include:

- Coffee and tea

- Nuts and dried fruit

- Rice and grains

- Snack foods

- Baked goods

- Health and beauty

- Pet food

- Home and garden

Flat Pouch(aka 2 or 3-sided seal)

The flat pouch gets its name from being completely flat with no gussets. It may also be referred to as a two-sided or three-sided seal pouch depending on the number of finished seals. This format is highly popular for one-time use products such as condiments and sauces, however, you can add a reclosable zipper to make the pouch reusable.

Flat Pouch applications

The flat pouch can be used for many food packaging and retail applications. Some of the most common and popular markets include:

- Coffee and tea: fraction (frack) packs

- Nuts and dried fruit: snack size

- Rice and grains: sacks

- Snack foods: individual servings

- Baked goods: wraps, pita bread

- Health and beauty: sample sizes

- Pet food: pet food treats, sample sizes

Spout Pouch

Beverage, Sauce, Squeeze Food Packaging

Liquid pouch is used for beverage,sauce or squeeze food & non-food packaging, with a diverse range of spouts, which comprises of Tamper-Evident, Flip-Top, Screw Cap Spout and Butterfly Spout Tap that make liquid products easy to be used, clean and environmentally friendly.

The production cost of the liquid pouches are lower than cans, plastic bottles or glass bottles. The cost of transportation and storage are obviously reduced. Packaged product can quickly cool and keep low temperature.

BSY’s liquid pouch has a wide range of materials, sizes, spout shapes, printing services, labels, brand customization and so on, to suit your brand style.

Functional Enhancements

Usually, some of the scope of application is more specific, such as the degassing valve used in coffee pouches,

pouches spout used for squeeze food.

More widely using, like rounded corner – any bag can be rounded.

- Reclosable Zipper

- Degassing Valve

- Pouches Spout

- Packaging Pouch Handle

- Pouches Window

- Glossy or Matte Finishes for Pouch

- Pouch Rounded Corner

- Tear Notches

- Hang Holes

Common Structures

- PET / FOIL / LLDPE

- PET / LLDPE

- MPET / LLDPE

- BOPP / LLDPE

- PET / MPET / LLDPE

- KRAFT / MPET / LLDPE

- BOPP/MPET/PE

FREE OF CHARGE

Contact us now ! You will get the following 2 parts

1.Free Sample

2.Basic Flexible Packaging Design Tmplates

CONTACT US NOW