Food Packaging Pouches by reason of the characteristics of laminated film, Usually, they have good water resistance, oil resistance, air tightness, and printed. Can meet the needs of most of the different attributes of products, such as (liquid, solid, paste, powder, etc).

These laminated layers materials , which forms a barrier to protect food from the erosion of light, oxygen and moisture.

High-quality packaging materials can be high temperature resisting steaming or boiling and cold storage, and have good Impact resistance and tear resistance can deal with all kinds of harsh transportation storage environment.

Besides, they offer a unique look and texture for packaging that will attract your customers surely.

Certainly, although the 2~3 laminated layers films materials bag limited function, but can be recombination by increasing the number of laminated films to achieve more stringent packaging requirements, while reducing packaging costs. Such as up to 10 layers above the composite laminated films structure.

Common Pouch Structure

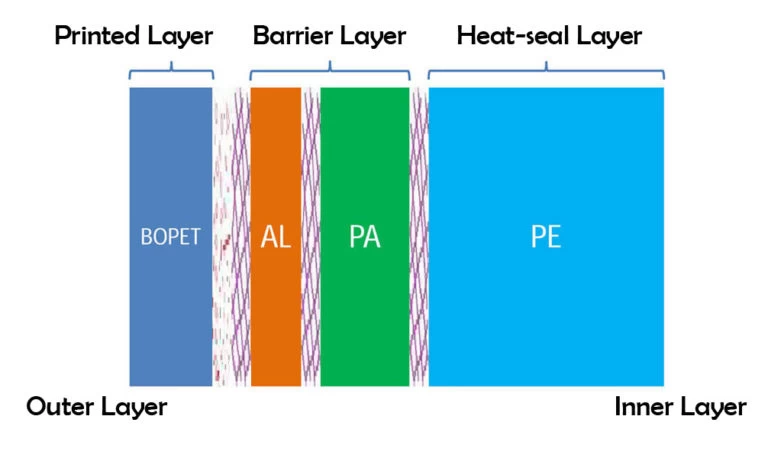

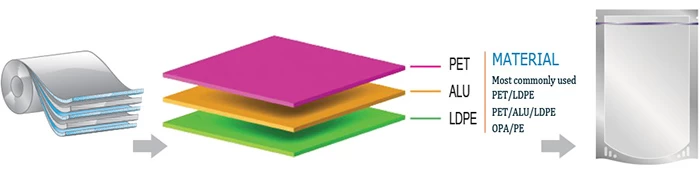

Following is the commonly used bag structure for reference(Take the three-layers structure as an example)

Commonly used outer layer material : PET, BOPP, NY/ONY/PA , etc.

(Printed Layer)

Commonly used middle layer material : AL, VMPET, VMCPP, PET, NY/ONY/PA, K-BOPP/PET/ONY, EVOH, Paper, etc.

(Barrier Layer)

Commonly used inner layer material : CPP, EVA, PE(LDPE/LLDPE)

(Heat-seal Layer)

AS Shown in :