- Browse Categories

- Biodegradable Packaging Bag

- Pet Food Bag

- Coffee &Tea Bag

- Stand Up Bag

- Gusseted Bags

- Flat Bottom Bag

- Spouted Pouches

- Special-shaped Bag

- Recyclable Pouches

- aluminum foil bags

- Cold Seal Roll

- Flexible Packaging Films

- Contact Us

-

We excel in providing medium to large bags of ready-made bags. MOQ: Generally 20000 bags. Large bags in size may have a minimum order quantity.

We do not supply storage bags at this time.Contact Now

Chocolate packaging bag / pouch

- Up to 11 color printing

- Maximum Width: 63"

- Maximum gauge 12 mil

- Variety of film structures

- In-line Lamination

- Custom features available upon request

Chocolate packaging bag / pouch

BSY Packaging produces cold seal rolls are the perfect packaging option for heat sensitive products. Cold seal packaging can be used in place of heat-sealing in order that product don’t lose kind and form once they need been sealed. we offer inventive and distinctive styles for our cold seal rolls that make sure that the product look appealing and interesting to shoppers.

Cold seal packaging is employed for varied product like:

Chocolate bars

Confectionery

Cookies

Ice cream

Pastry

Cereal bars, among others.

Darrell Lea is an Australian company that manufactures and distributes chocolate, liquorice and other confectionery.

They chose BSY cold seal packaging manufacturers to customize the perfect packaging for their confectionery.

Production Process

We use the latest high-speed fixed-point coating compound machine to

carry out cold-adhesive coating compounding at fixed-point parts.

Choose the best materials for your packaging

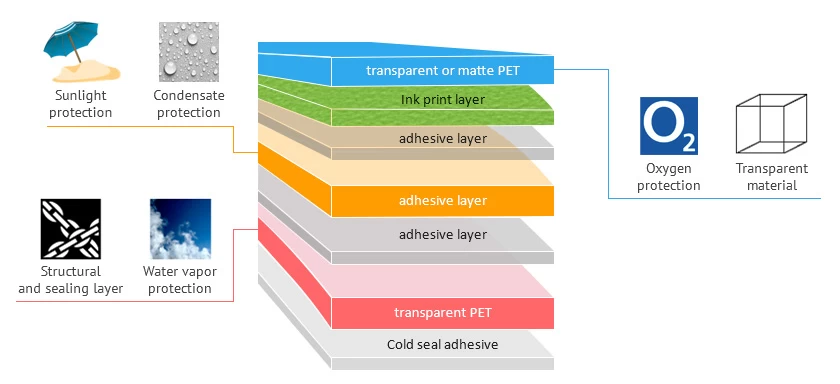

Chocolate and stick candy is extremely vulnerable to sunlight and also needs protection against oxygen, especially if there are nuts inside, so the composite materials should preserve the initial gas composition and light level in the packaging.

SCHEME 1 : The optimal for group chocolate sweets packaging. It is a three-layer laminate that will protect the product from sunlight and oxygen.

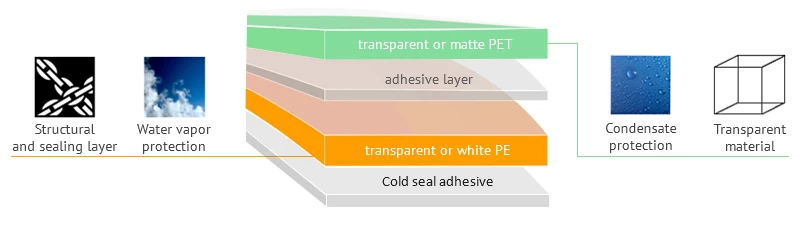

SCHEME 2 : is a two-layer laminate. The choice between transparent or non-transparent composite depends on whether the customer wants a look-through part for product display.

- transparent or matte PET/BOPP (good barrier properties against water condensate, high transparency)

- transparent or white PE (sealing and structural layer, good barrier against water vapours, high transparency)